FEED/Studies | Tenders | Projects

JSB Subsea has vast experience throughout the life cycle of global projects, from initial FEED study through to offshore installation, and project completion.

Projects | Tenders | Studies

JSB Subsea has vast experience throughout the life cycle of global projects, from initial FEED study through to offshore installation, and

Completed Projects

Hawar Project

Execution Year:

2021

Position:

Engineering Manager (Supporting role)

Contractor:

Al Gihaz Contracting / Enshore

Installation Vessel:

Atlantis Barge (Shallow water barge modified for cable lay)

Project background:

South Bahrain (Ras Al Bar) to Hawar Island

Installation of three (3) 25km 66 kV power cables (3 core, 6.8” OD) and one (1) bundled FOC (96 fibre, 20mm OD)

Jet and rock trenched throughout length.

Extensive UXO survey and clearance.

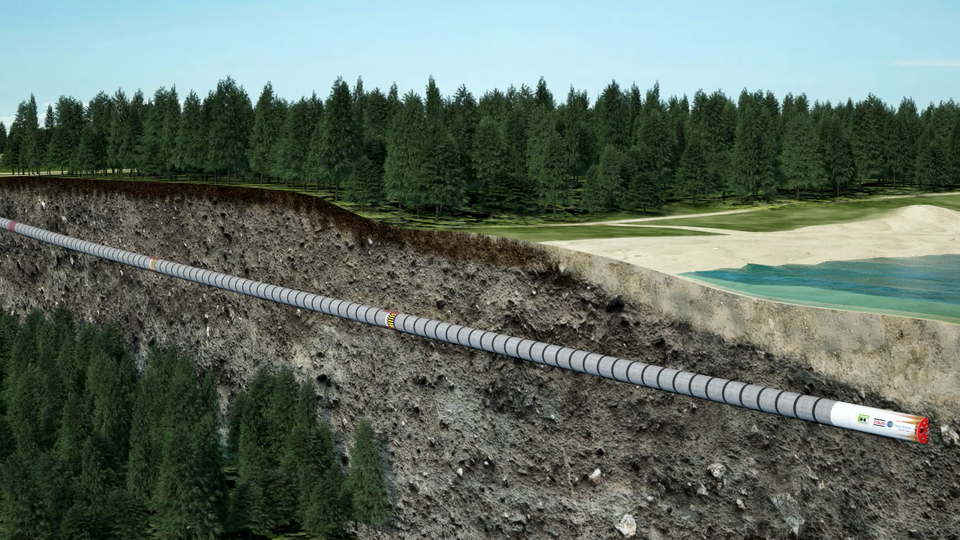

Nord Stream 2 Project

Execution Year:

2018

Position:

Landfall Pull-in Engineer (Supporting role)

Contractor:

Saipem Ltd

Installation Vessel:

Castro 10 (S-Lay Vessel)

Project background:

Location: Lubmin, North East Germany

Pull-in of two (2) 48” diameter gas pipeline through two (2) microtunnel’s

Aasta Hansteen Project

Execution Year:

2016

Position:

Lead Pipeline Installation Engineer

Contractor:

Subsea 7

Installation Vessel:

Seven Oceans (Reel Pipelay Vessel)

Project background:

1300m WD – Norwegian Sea (Artic Circle)

4 x 12” BuBi 316L Lined Pipeline

3 x 12” Met-Clad 316L SCR

1 x 14” CS SCR

Including PLET structures, in-line distributed buoyancy, various transition joints, holdback anchors

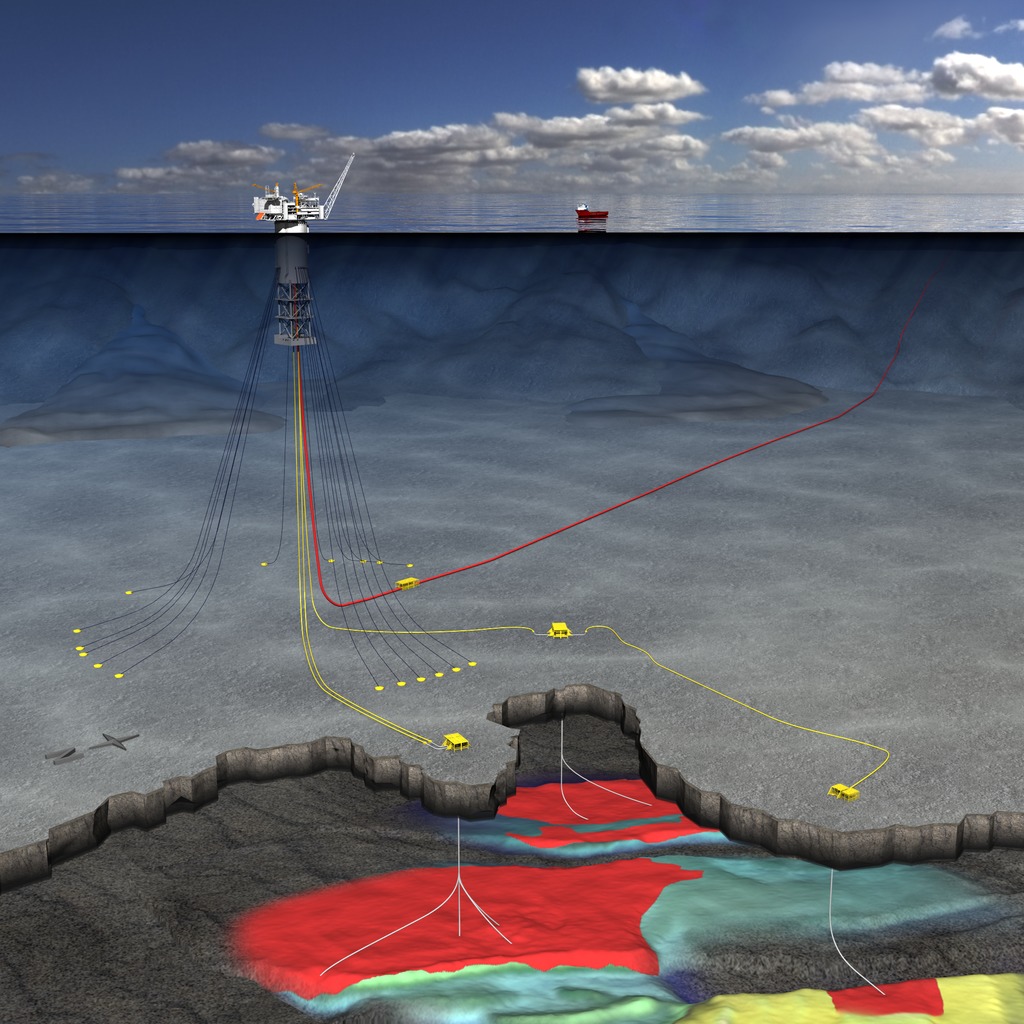

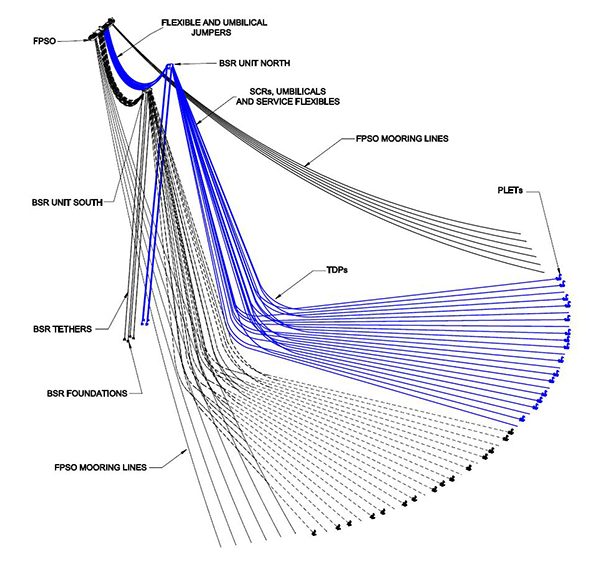

Guara Lula Project

Execution Year:

2013

Position:

Snr Pipeline Installation Engineer (Offshore Support)

Contractor:

Subsea 7

Installation Vessel:

Seven Oceans (Reel Pipelay Vessel)

Project background:

2,100m WD – Santos Basin, Brazil

27 x 3.9km BuBi Lined SCRs

27 x suction anchors

4 x 2000Te Subsea Buoys

Laggan Tormore Project

Execution Year:

2012

Position:

Snr Pipeline Installation Engineer (Offshore Support)

Contractor:

Subsea 7

Installation Vessel:

Seven Oceans (Reel Pipelay Vessel)

Project background:

640m WD – West of Shetland

6”/ 2” piggyback pipeline (using the automated piggyback machine)

Including ILT/PLET structures

Katy Development Project

Execution Year:

2012

Position:

Lead Pipeline Installation Engineer

Contractor:

Saipem Ltd

Installation Vessel:

Helix Express (Reel Pipelay Vessel)

Project background:

80m WD - North Sea (UK)

14Km of 10” Gas and 2” MEG Piggyback Pipelines

K4Z Marine Operations Project

Execution Year:

2012

Position:

Lead Pipeline Installation Engineer

Contractor:

Saipem Ltd

Installation Vessel:

Helix Express (Reel Pipelay Vessel)

Project background:

80m WD - North Sea (UK)

17Km of 6” Gas Pipeline – Logstor Foam Insulated Coating

Jet Trenching Operations

Ekofisk LoFS Project (Ph2)

Execution Year:

2010

Position:

Project Engineer

Contractor:

CTC Marine Projects Ltd

Installation Vessel:

Volantis (MSV with c/w permanently mobilised UT1 Jet Trencher)

Project background:

North Sea (NCS, block 2/4) – 75m WD

200km of Fibre-optic LoFS System

Equipment development of Cable Deployment System (CDS) and Cable Pick Up System (OPUS) and project specific trencher Modifications.

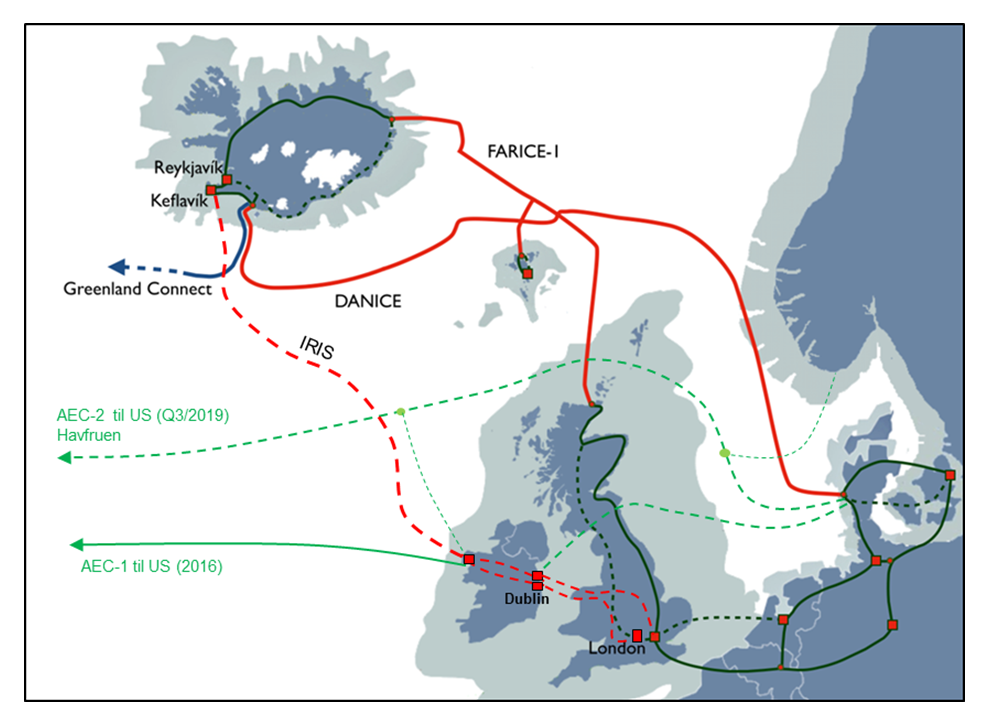

Danice Submarine Cable Project

Execution Year:

2008

Position:

Project Engineer (Offshore Support)

Contractor:

CTC Marine Projects Ltd

Installation Vessel:

OSV Relume (Multipurpose Support Vessel) c/w Jet Trencher CMROV4

Project background:

Iceland to Denmark

The Danice cable is 2,300km linking Denmark and Iceland. The cable was simultaneously laid and ploughed using the CS Global Sentinel vessel. CTC were responsible for jet trenching the cable crossing locations to maximise burial potential of the cable.

Ekofisk LoFS Project (Ph1)

Execution Year:

2009

Position:

Project Engineer

Contractor:

CTC Marine Projects Ltd

Installation Vessel:

Deep Cygnus (Multipurpose Support Vessel)

Project background:

North Sea (NCS, block 2/4) – 75m WD

Pre-Installation operations for LoFS System (Riser, GRP, Back-bone Cable installation)

Robin Rigg Windfarm Project

Execution Year:

2009

Position:

Project Engineer (Pull-in Lead)

Contractor:

CTC Marine Projects Ltd

Installation Vessel:

Union Beaver (Anchor Barge converted to Cable Lay)

Project background:

Solway Firth (Scotland, UK) – 35m WD

Installation and pull-in of the inter-array FOC/Power cables between 60 Vestas V90-3MW wind turbines

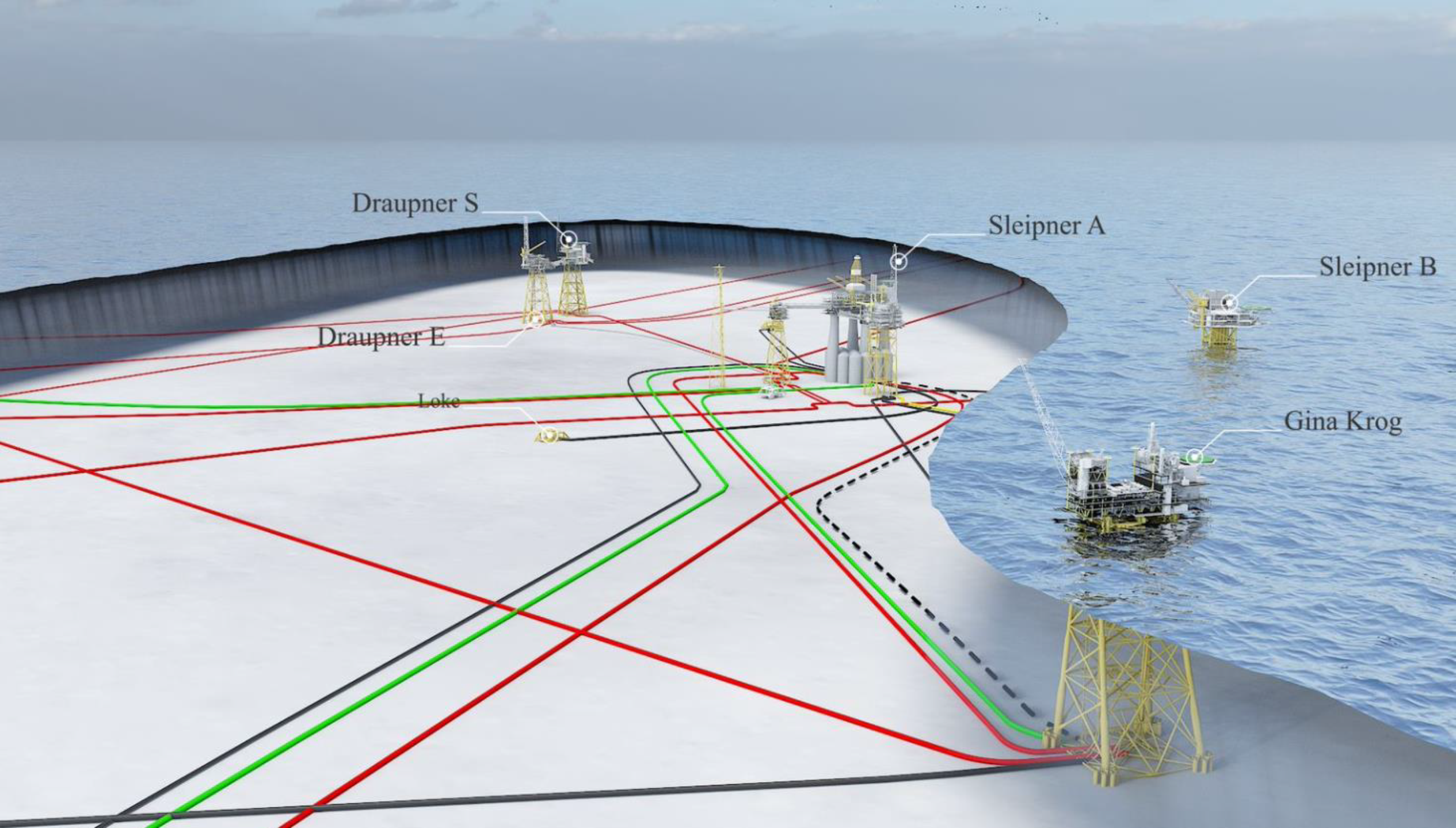

Gina Krog Alternative Oil Export

Execution Year:

2023/24

Position:

Equinor Package Lead - Pipeline

Installation Contractor:

TechnipFMC

In-place Design Contractor:

IKM Ocean Design

Installation Vessel:

DeepEnergy (Reeled Pipelay Vessel)

Project background:

Norwegian Sea (NCS, block 15/5P) – 120m WD

10.75” X65 Oil Export Pipeline, tie-in at Sleipner Platform via a decommissioned pipeline, tie-in to Gina Krog Platform via a live export pipeline using a Moregrip connector, subsea dredging, subsea coating removal, subsea pipeline cutting, subsea pipeline scanning, spool installation, rock dumping.

Kristin Sør Project

Execution Year:

2023

Position:

Equinor Package Lead - Pipelines

Installation & In-place Design Contractor:

TechnipFMC

Installation Vessel:

DeepEnergy (Reeled Pipelay Vessel)

Project Responsibilities:

Norwegian Sea (block Blocks 15/8 (NCS) and 16/18a (UKCS) – 360m WD

1x 10/16 Pipe-in-Pipe (PIP) production pipeline c/w BuBi 316L Lined Pipeline, 2x 3” MEG pipelines, 1x off ILY on PiP, 2x PLET structures, residual curvature, HPHT, Installation of an ITS structure (240Te), and rigid spools.

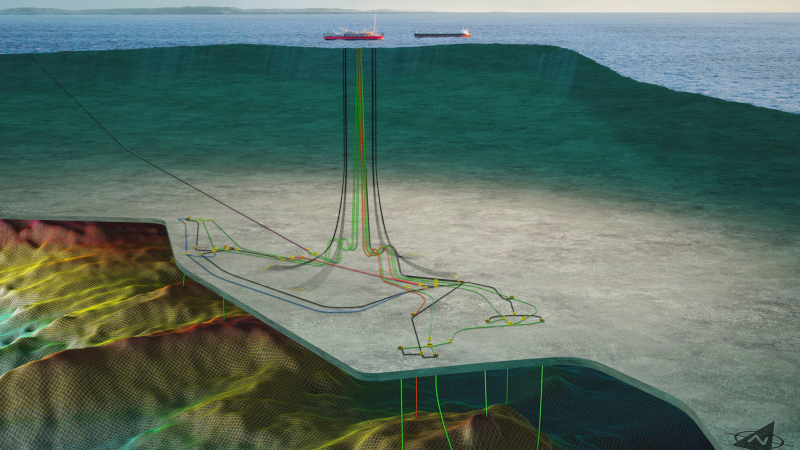

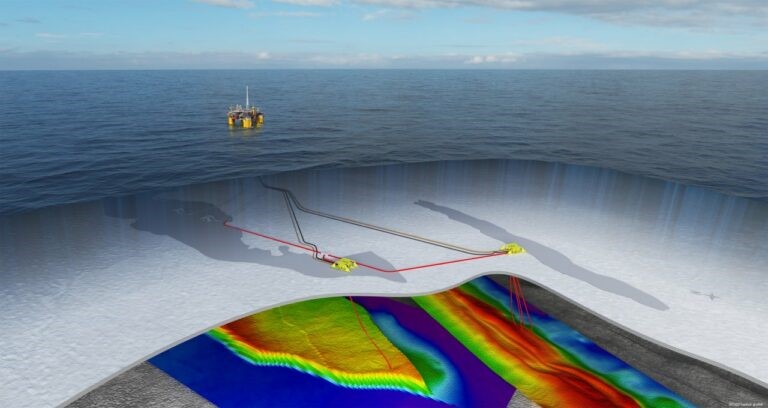

Raia Project (prev BM-C-33)

Execution Year:

2025

Position:

Equinor Package Lead - Flowline Design/Installation

In-place Design & Installation Contractor:

TechnipFMC (Paris/Rio)

Installation Vessel:

Deep Blue (Reeled Pipelay Vessel)

Project background:

The field is in water depths up to approximately 2,900 meters.

TechnipFMC's Subsea 2.0 tree systems, manifolds, jumpers, risers and flowlines, umbilicals, pipeline end terminations, subsea distribution and topside control equipment, and installation. The company will also be responsible for life-of-field services